Shoulder Screw Buyers Guide

Common Applications of Shoulder Screws

Bearings can be mounted on the shoulder to create simple cam followers. Components such as pulleys, gears and sprockets will rotate on the shoulder at moderate speeds. Springs are used on the shoulder to preload components traveling axially along the length of the shoulder. The screws are used as axles for rolling parts, as pivot points, as mounting pins and as guides in sliding elements.

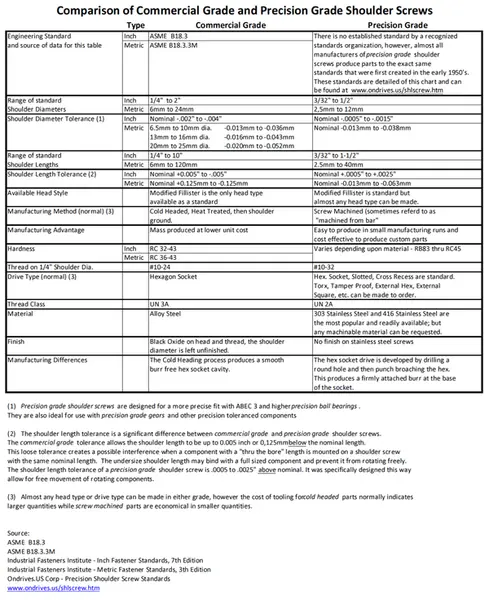

Commercial vs. Precision Grade

There are two basic shoulder screw categories: “Commercial Grade” and “Precision Grade”. Precision grade shoulder screws differ from commercial grade in that they have tighter shoulder diameter and shoulder length tolerances and are ideal for use with ball bearings and other precision components. Both grades of shoulder screws are available in inch and metric sizes.

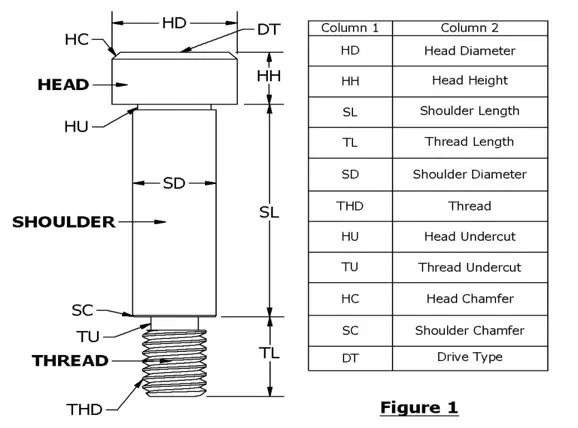

Anatomy of a Shoulder Screw

The shoulder screw is comprised of three main features: The “head” which is the largest diameter, the “shoulder” which is described by its diameter and length and the “thread” whose major diameter must be slightly smaller than the shoulder diameter.

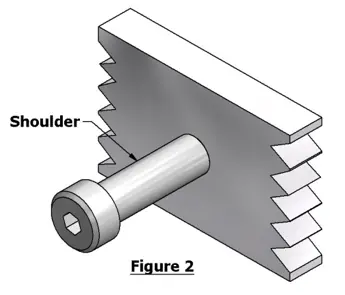

When the thread of the shoulder screw is fully installed, the unthreaded portion extends beyond the thread and creates a journal (Fig. 2). This journal is fully functional as a shaft or dowel for rotating items such as bearings and bushings as well as for sliding applications such as punch and die pins.

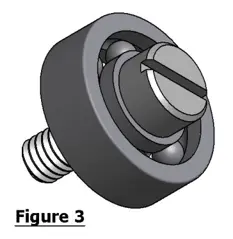

When mounting ball bearings, proper shoulder length and tolerances permit the screw to fix the inner race of the ball bearing and prevent it from rotating while still allowing the outer race to spin freely; thus creating a simple cam follower (Fig. 3). Shoulder screws can also be used to create a pivot point as in the case of a ratchet and pawl assembly (Fig. 4).

In addition, compression springs and sliding components can be mounted on the shoulder to allow axial motion. The sliding component is captured on the shoulder between the head of the screw and the mounting surface.

How Shoulder Screws Are Specified

Unlike most machine screws, which are specified by thread size and thread length, shoulder screws are specified by shoulder diameter and then by shoulder length. Whereas a 1/4” x 1” machine screw describes a 1/4” diameter thread and 1” long under the head, a 1/4” x 1” shoulder screw will have a shoulder diameter of 1/4” and a shoulder length that is 1” long. The overall length of the shoulder screw will include the head height, the 1” shoulder length and the thread length.

A wide range of shoulder diameters are available and each diameter is available in a range of shoulder lengths. Both inch and metric sizes are produced as standards. Custom or made to order screws are offered by a variety of manufacturers. Materials include but are not limited to hardened alloy steel, mild steel, 300 series stainless steels, pre-heat treated 416 stainless steel, 17-4 hardened stainless steel, brass and plastics.

Standard shoulder screws are offered with pre-selected thread sizes but any thread size can be made to order. The one limiting factor to the thread size is that the thread major diameter must not exceed the shoulder diameter. This is necessary to allow components to pass over the thread and slide onto the shoulder.

History and Development

Prior to the 1950’s the only standard shoulder screws available were made of hardened alloy steel and supplied with a hex socket drive. The smallest shoulder diameter was one quarter inch. The engineering standard for these shoulder screws is detailed in ASME B18.3 for inch sizes and ASME B18.3.3M for metric sizes.

To the best of my knowledge, sometime in the early 50’s, a small company, which has long since gone out of business, introduced a limited range of shoulder screws made from 303 stainless steel. This new line of shoulder screws was made to tighter tolerances on the shoulder diameter and shoulder length. At first, only 1/8”, 3/16” and 1/4” shoulder diameters were offered and the complete range included only 27 sizes and they were available only as slotted drives.

To distinguish this new range of screws from the industry standard alloy steel screws, they were marketed as “Precision Shoulder Screws”. By inference, the industry standard alloy screws began to be referred to as “Commercial Grade”. These classifications persist today and express the basic differences between the two grades. (See the comparison chart on page 4)

Over the years, the range of sizes offered in precision grade shoulder screws has expanded considerably. Both smaller and larger shoulder diameters and their associated range of shoulder lengths have been added. Standard precision grade shoulder screws are available in diameters from 1/8” to ½” diameter. Just a few years ago, a standard selection of “miniature” shoulder screws were made available. These have a 3/32” shoulder diameter and lengths from 3/32” to 1/2”. A limited list of standard “low head” shoulder screws is also available. Both can be found at www.ondrives.us/precision-fasteners/shoulder-screws.

Other drive types such as hex socket drives and cross recess (Phillips) drives have become available as standards. The tolerance standards first created by the original manufacturer still persist although there is no established standard for precision grade shoulder screws by a recognized standards organization. A complete list of available standard, precision grade shoulder screws can be found at www.ondrives.us/precision-fasteners/shoulder-screws.

The following chart provides the major differences in the two classifications:

TERMINOLOGY AND FEATURES:

Stripper Bolts:

This is a term often used to specify shoulder screws when used in punch and die mechanisms or plastic injection mold sets. The screws act as linear slides to accurately align the die or mold halves as they open or close.

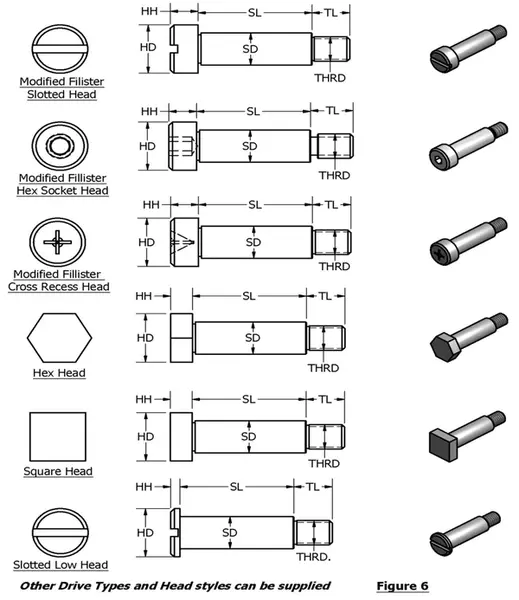

Drive Types:

Commercial grade, alloy steel shoulder screws are supplied almost exclusively with Hex Socket drives. Precision grade shoulder screws are readily available in Slotted drive and Hex Socket drive and to a lesser degree, in Phillips drive. Torx drive, Star drive, Tamper Proof drives, Square Head drive or Hex Head drives can also be supplied. (Fig. 6)

Contact Ondrives for Your Shoulder Screw Needs Today

Ondrives.us has many materials for your project and can help you have the perfect shoulder screw your applications. Contact us to discuss your needs or request a quote and we'll get back to you shortly!PDF Version